Okay, so I’ve been wanting to try making my own moonshine for a while now. It just sounds like a fun, kinda rebellious project, you know? I finally decided to give it a go, and let me tell you, figuring out the ingredients was the first big hurdle. I wanted something simple, but authentic-ish.

Getting Started: The Basic Idea

I did a bunch of reading, watched some videos (some more sketchy than others, I’ll admit), and realized that at its core, moonshine is just about fermenting sugar and then distilling it. The “mash” is what you call the mixture you ferment. So, I needed to figure out my mash ingredients.

My Ingredient List

I decided to go with a pretty classic corn-based recipe. Here’s what I ended up using:

- Cracked Corn: I used about 8.5 pounds of this. It’s basically just dried corn kernels that have been coarsely ground. Got it at a feed store – way cheaper than buying it online!

- Sugar: Plain white granulated sugar, about 7 pounds. This boosts the alcohol content. Some folks use all corn, but I wanted to make sure I got a decent yield.

- Water: I used about 5 gallons of filtered water. Gotta make sure it’s clean, no chlorine or anything that could mess with the yeast.

- Yeast: I used a distiller’s yeast, got it at a online store that sell this type of goods. It’s designed for this kind of thing and can handle higher alcohol levels.

- Malted Barley:Just 1 pound.I added the malted barley for enzymes to help to convert.

The Mashing Process (My Experience)

First, I heated up the water in a big pot – like, really big. It needs to be hot, to get the corn to soften up. Once it was simmering, I dumped in the cracked corn. Stirring that much corn was a workout! I kept it at a low simmer for about an hour, stirring every now and then, so it wouldn’t stick to the bottom.

After the hour, I let it cool down a bit. This is important – you don’t want to kill the yeast by adding it to boiling hot water. I added malted barley and * it’s cool enough I stirred in the sugar until it was all dissolved. It took a while, and my arm got another workout.

Then, I carefully poured the whole mixture into my fermenting bucket. Made sure the bucket was clean and sanitized, of course. Once the mash was cooled down to the right temperature (the yeast package had instructions), I sprinkled in the yeast. Didn’t stir it in, just let it sit on top.

Finally, I put the lid on the bucket, attached an airlock (that bubbly thing that lets gas escape but keeps air out), and put it in a cool, dark place. Now it’s just a waiting game! It’s supposed to bubble away for a week or two, and that’s when the magic happens – the yeast turns the sugar into alcohol.

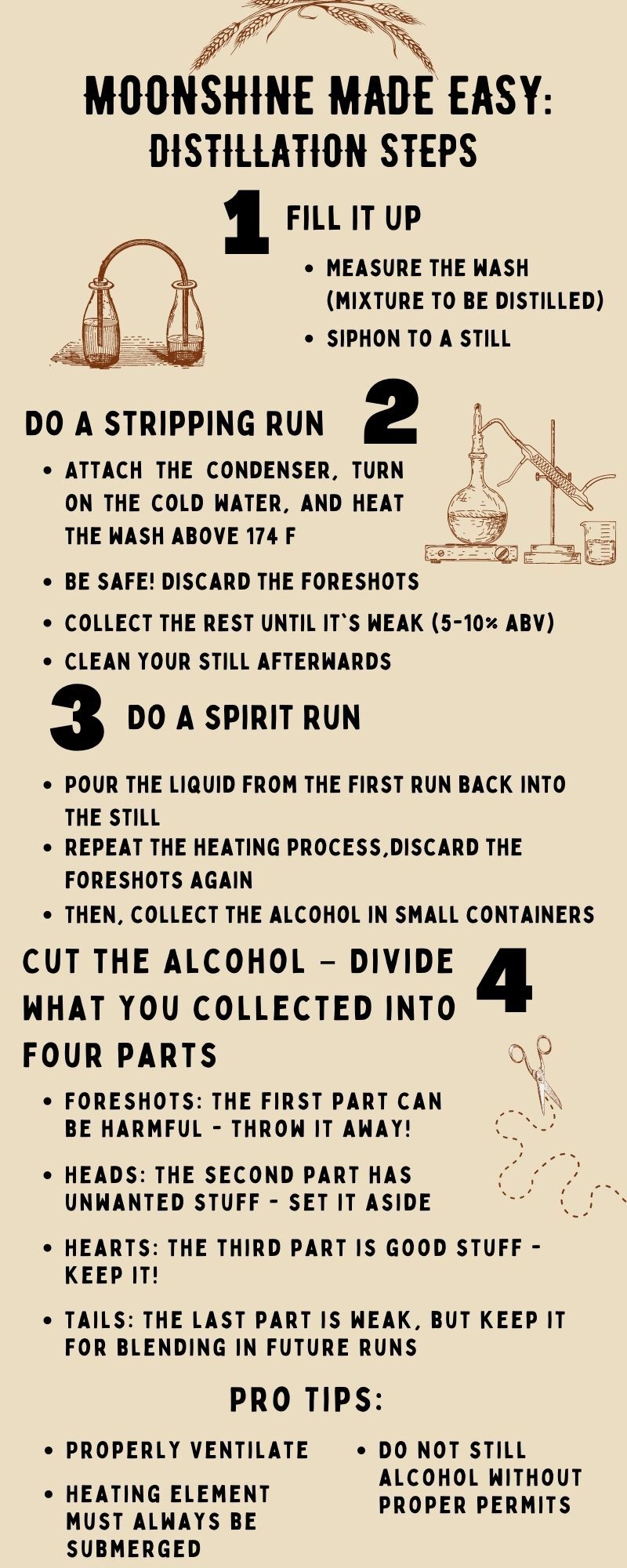

I’m still in the middle of this whole process, so I’ll have to update you on how the distillation part goes. But getting the mash right felt like a major accomplishment. Wish me luck!