Alright, so today I’m gonna walk you through how I tackled cleaning procedures for a commercial kitchen. It’s all about keeping things sanitary and efficient, so let’s dive in.

First things first, I grabbed all the necessary supplies. We’re talking about industrial-strength degreaser, sanitizer, good ol’ dish soap, different colored microfiber cloths (color-coding is key!), scrub brushes, and of course, gloves and eye protection. Safety first, always!

Then, I started with the “dry” stuff. I mean, sweeping and wiping down all surfaces to remove any loose food particles or debris. I focused on the floor, countertops, and any equipment exteriors that were easily accessible. Getting rid of the big chunks makes the actual cleaning process way easier.

Next up was the dishwashing station. I emptied and pre-soaked all the dishes and utensils. Then, I gave the sinks a good scrub with dish soap and hot water, making sure to rinse thoroughly. After that, I loaded up the commercial dishwasher (if you have one). If not, it’s the classic three-compartment sink routine: wash, rinse, sanitize.

Okay, now for the real grime – the cooking equipment.

- Ovens: I tackled the ovens first. I let them cool down completely, then scraped out any burnt-on food. After that, I sprayed them down with a heavy-duty oven cleaner and let it sit for the recommended time. Finally, I scrubbed the inside with a tough brush and rinsed everything super well.

- Grills and Stovetops: These are usually the dirtiest. I used a scraper to remove any hardened grease and food residue. Then, I applied a degreaser, let it soak, and scrubbed with a grill brush. After that, I wiped everything down with a clean, damp cloth.

- Fryers: Cleaning fryers is a whole other beast. First, I let the oil cool completely. Then, I drained it and filtered it (if it was still usable). I scraped out any sediment and then cleaned the fryer with a special fryer cleaner. Don’t forget to clean the fryer baskets too!

After the major equipment, I moved onto the smaller appliances – blenders, food processors, mixers, etc. I disassembled them as much as possible and washed all the removable parts with soap and water. The bases were wiped down with a damp cloth and sanitized.

Floors were next. I used a degreasing floor cleaner and a mop (or a floor scrubber if you have one) to clean the entire kitchen floor. I paid special attention to areas around the cooking equipment where grease tends to accumulate.

Don’t forget the walls and ceilings! These often get overlooked, but they can collect grease and dust. I wiped them down with a damp cloth and a mild detergent, paying attention to any areas near the cooking equipment.

Finally, I sanitized all surfaces that come into contact with food – countertops, cutting boards, utensils, etc. I used a food-safe sanitizer and followed the instructions on the label.

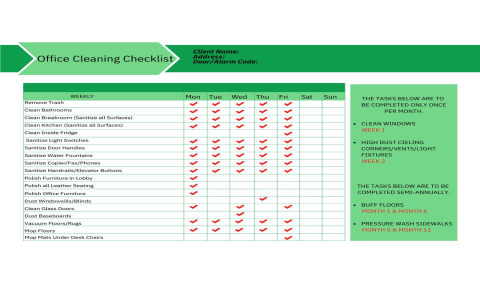

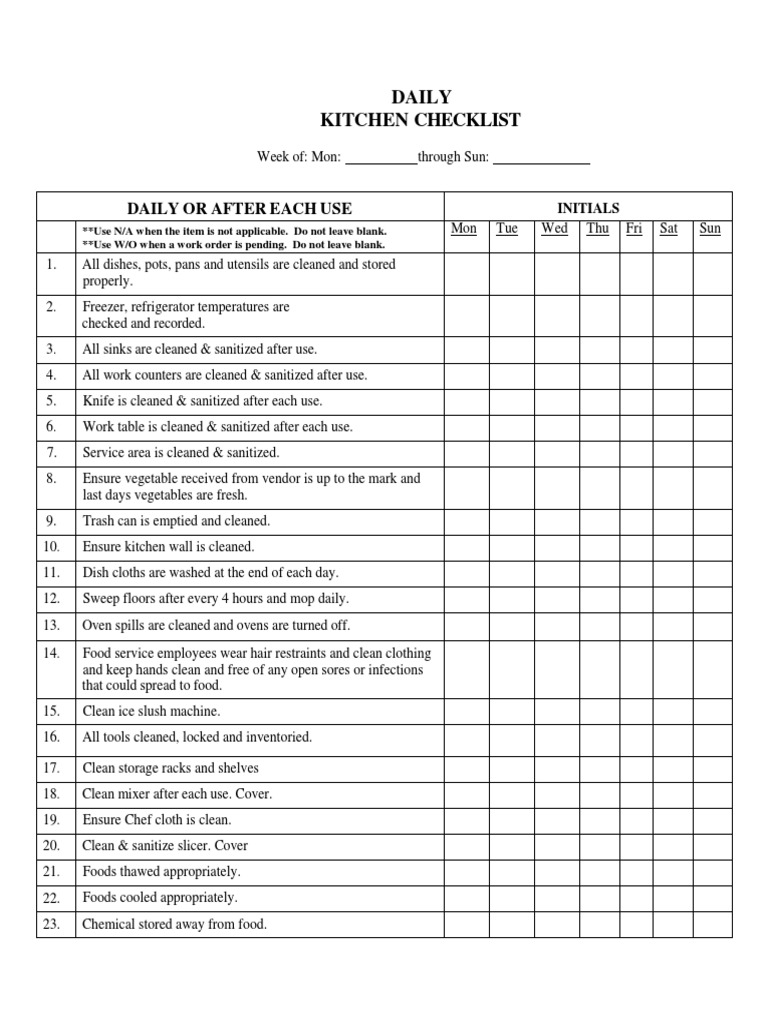

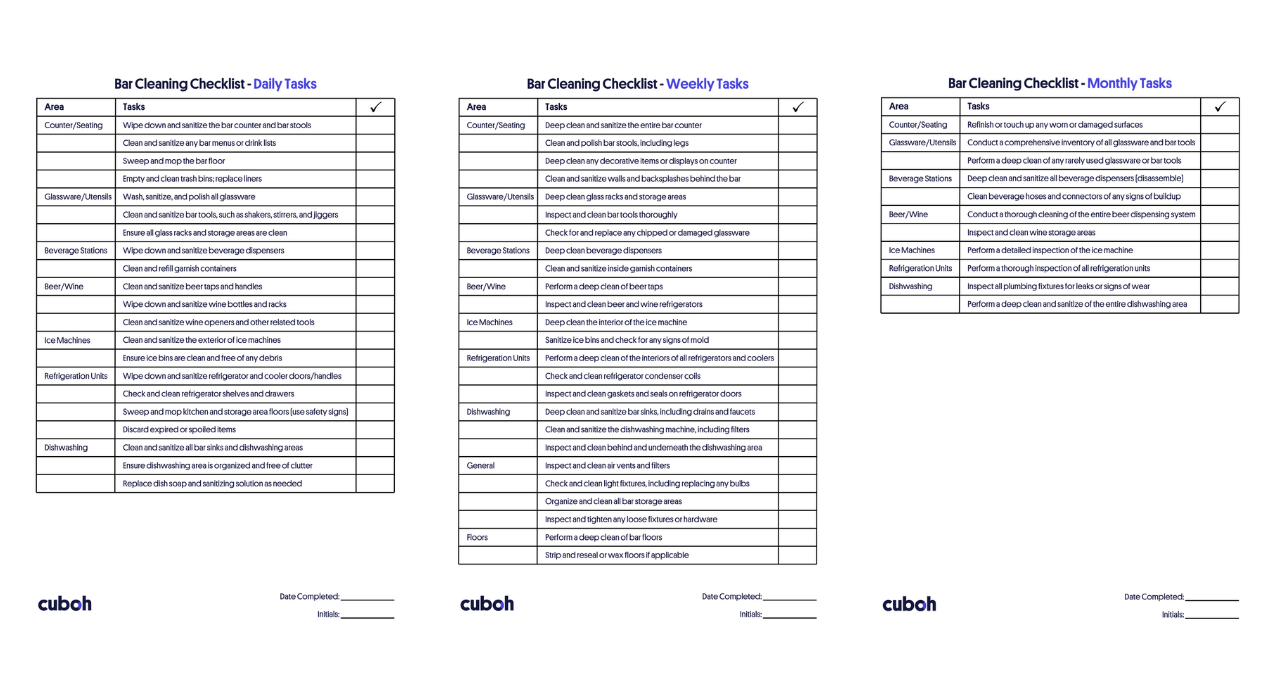

And that’s pretty much it! It’s a lot of work, but a clean commercial kitchen is essential for food safety and efficiency. The key is to break it down into manageable steps and to be consistent. We tried to create a schedule and checklist based on these procedures so everyone on the team knew what to do and when to do it. It definitely helped!

Pro Tip: Keep a log of cleaning activities. This helps you track what has been cleaned and when, and it’s also useful for inspections.

Another Pro Tip: Train your staff properly on cleaning procedures. Everyone needs to be on the same page and understand the importance of food safety.

Hope this helps anyone starting out! It’s all about practice and refining the process to fit your own needs.